During rotation, the sealing lip rubs against the counter face under a contact pressure calculated to achieve a sealing function. The seal also operates as a deflector ring, and its centrifugal action contributes to good sealing function. Due to the effect of centrifugal force, the sealing lip tends to reduce its contact pressure with increasing speed.

Directions of shaft design and fitting are provided the two different of types RE/RB and RE1/9RB.

Gamma seal type RE/RB and RE1/9RB consists of an elastic sealing member and a metal case. The case serves as a holder, support and protection for the sealing member and constitutes a very effective deflector. The components are not bonded to each other, the rubber-sealing member is stretched and held in the case by its elasticity.

Type RE/RB and RE1/9RB provides a very narrow installation width,

this seal to be used in assemblies where other seals could not be installed due to lack of space.

The seal is press fitted on the shaft, and no other means of fixing is required.

The Gamma seal is primarily intended for sealing against foreign matter, liquid splatter, grease.

The foremost features of the Gamma seal are:

- very narrow installation width

- friction diminishes with increasing rotational speed

- centrifugal action contributes to good sealing

- lower demands on surface smoothness, surface hardness and tolerances

- mechanical protection

- easy to fit

Prior to being fitted, the sealing member shall be greased, but not between the sealing member and the case. It is important that the seal be fitted with adequate precision. The seal shall be pressed onto the shaft with a uniform and even pressure.

The case must not be tapped directly with the hammer. The seal should therefore be pressed to the right position by means of a suitable assembly tool .

The style of the Gamma seal is as follows:

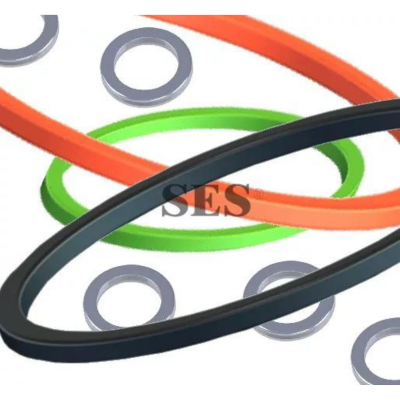

Gamma seals are available in a choice of materials including:

|

Rubber Material |

metal Material |

Surface Treatment |

||

|

NBR |

Carbon Steel |

CR3 |

||

|

VITON (FKM) |

Stainless Steel 304 |

ZnNi |

||

|

EPDM |

Stainless Steel 316 |

|||

|

HNBR |

||||

|

SILICONE |

[VIP The 2 year ] Index:5

[VIP The 2 year ] Index:5