The red Teflon coating on the inner side of the pulley increases the sliding self-lubrication of the pulley ball, reduces the frictional resistance with the pulley ball, and improves the durability.

The side basket of the pulley is designed to be empty to facilitate cutting/heat dissipation and maintain the highest efficiency of the CVT.

The torque disc is made of high-strength 6061-T6 aluminum alloy material, which is more engaged with the belt joint surface, improves the friction coefficient and reduces power loss.

The guide pin of the torsion plate slide rail adopts the separation design of the shaft sleeve and the shaft center, which makes the torsion plate act more smoothly, and effectively

reduces the wear and reaming of the groove of the slide rail.

The grooves of the torsion disc slide rail can be changed between 45° and 55°, which can be changed at any time according to the riding needs.

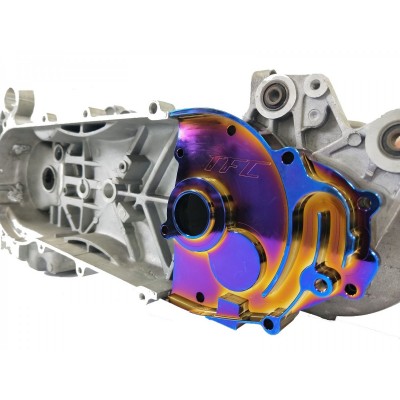

clutch cover

The clutch cover is designed with sandblasted drilling.

The drilling design can evacuate chips by itself, reduce the formation of dust and reduce the possibility of slippage.

The sandblasting design is effective and quick to break in, quickly reaches the best contact area, and provides stronger bite force.

The shape of the clutch cover body is CNC machined, with extremely high roundness, reducing the possibility of high-speed yaw vibration.